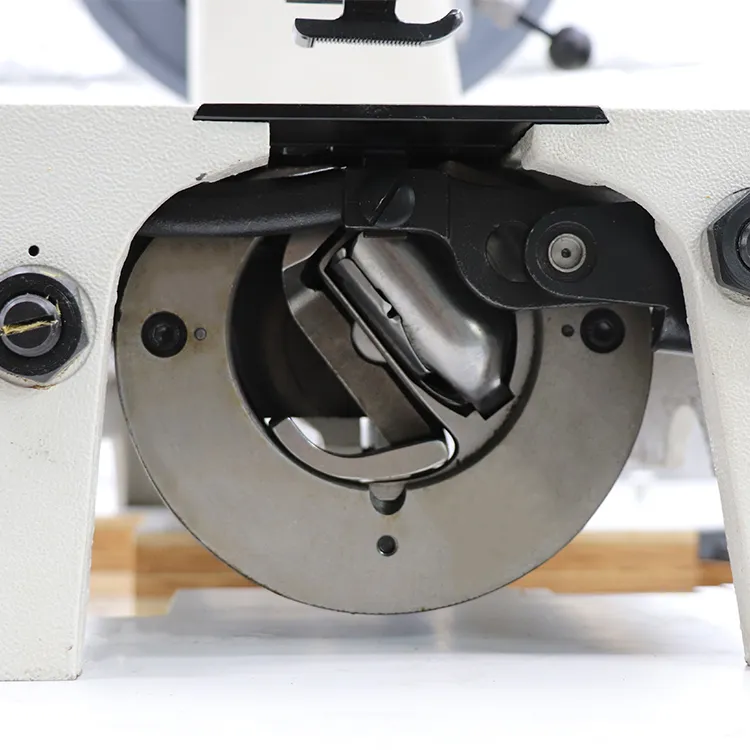

industrial bag closing machine head

Latest articles

industrial bag closing machine headFor those new to sewing or looking to streamline their process, the walking foot zigzag sewing machine offers ease of use. Setting up the machine with the walking foot is typically straightforward, and once in operation, it can significantly reduce the time spent on tedious tasks. The assurance that seams will be even and secure allows seamstresses to focus more on creativity and less on correction.

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

industrial bag closing machine headIn conclusion, the use of handheld sewing machines for thick fabrics is a growing trend that combines convenience with creativity. As technology progresses and more innovative models hit the market, we can anticipate even greater capabilities that allow crafters to explore their skills with various materials. By understanding the specific requirements of working with thick fabrics and investing in the necessary tools, sewing enthusiasts can unlock the potential of handheld sewing machines, making sewing a more accessible and enjoyable activity for everyone. Whether you're repairing a favorite pair of jeans or creating custom upholstery, these devices are equipped to handle the task, bringing vibrant creativity into the world of sewing.

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

industrial bag closing machine headBenefits of Using Handheld Sewing Machines for Thick Fabrics

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

industrial bag closing machine head2. Use a Walking Foot Some sewing machines may require you to purchase a separate walking foot attachment. Ensure that your machine is equipped with this foot to maximize its leather-sewing potential.

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

industrial bag closing machine headThe lockstitch sewing machine was first developed in the 19th century, with Isaac Merritt Singer often credited for popularizing it through his innovative designs. This machine revolutionized the textile industry, making it possible to sew pieces of fabric together faster and more precisely than ever before. The lockstitch mechanism, which interlocks threads from the needle and the bobbin, produces a strong and durable stitch that holds well under stress, making it ideal for various sewing projects.

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

industrial bag closing machine headRecommended Heavy-Duty Sewing Machines

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

industrial bag closing machine headIndustrial Sewing Machines: These machines often come with tables or workstations, requiring a dedicated space with ample room for operation and material handling.

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More- industrial bag closing machine head

...

industrial bag closing machine head 【industrial bag closing machine head】

Read More3. Join a Community Consider joining local workshops or online forums. Engaging with other leatherworkers can provide inspiration and valuable insights.

industrial bag closing machine head...

industrial bag closing machine head 【industrial bag closing machine head】

Read More

Popular articles

Flat bed sewing machines are a versatile and essential tool for anyone interested in sewing. Their simplicity, versatility, and durability make them suitable for a wide range of sewing tasks, from garment construction to quilting. Don’t miss out on the opportunity to enhance your sewing projects—buy a flat bed sewing machine today and experience the difference it can make.

In the paint industry, R996 enhances color retention and durability, while in plastics, it improves the product's UV protection and overall aesthetics In the paint industry, R996 enhances color retention and durability, while in plastics, it improves the product's UV protection and overall aesthetics

In the paint industry, R996 enhances color retention and durability, while in plastics, it improves the product's UV protection and overall aesthetics In the paint industry, R996 enhances color retention and durability, while in plastics, it improves the product's UV protection and overall aesthetics

This has led to the development of specialized grades tailored to specific industrial requirements This has led to the development of specialized grades tailored to specific industrial requirements

This has led to the development of specialized grades tailored to specific industrial requirements This has led to the development of specialized grades tailored to specific industrial requirements